Do you have the problem of insufficient pressure when using the cutting machine? Do you know why this happened? Today, the cutting machine manufacturer discussed with you the causes of insufficient pressure of the cutting machine, which are usually caused by the following reasons:

1、 Long term use of overpressure will also lead to insufficient pressure of the cutting machine.

2、 The large worktable is used for a long time with a small knife die, and it is used off center.

3、 Long term use of the knife die before and after use or left and right, and long-term use of the fixed position.

4、 The oil pump is the power of the whole cutting machine. If the oil pump is damaged or leaks oil, the pressure of the oil pressure cutting machine will be insufficient.

The secondary buffer valve is not closed.

The secondary buffer valve of the hydraulic cutting machine works under normal no-load conditions, but should be closed when the machine is pressurized. If the secondary buffer valve has been working, it is bound to affect the downforce of the hydraulic cutting machine; We can pressurize the machine, and the other can observe the indicator light of the buffer valve to see whether it is closed in advance before pressurizing. If not, please check the circuit; If yes, check the next item.

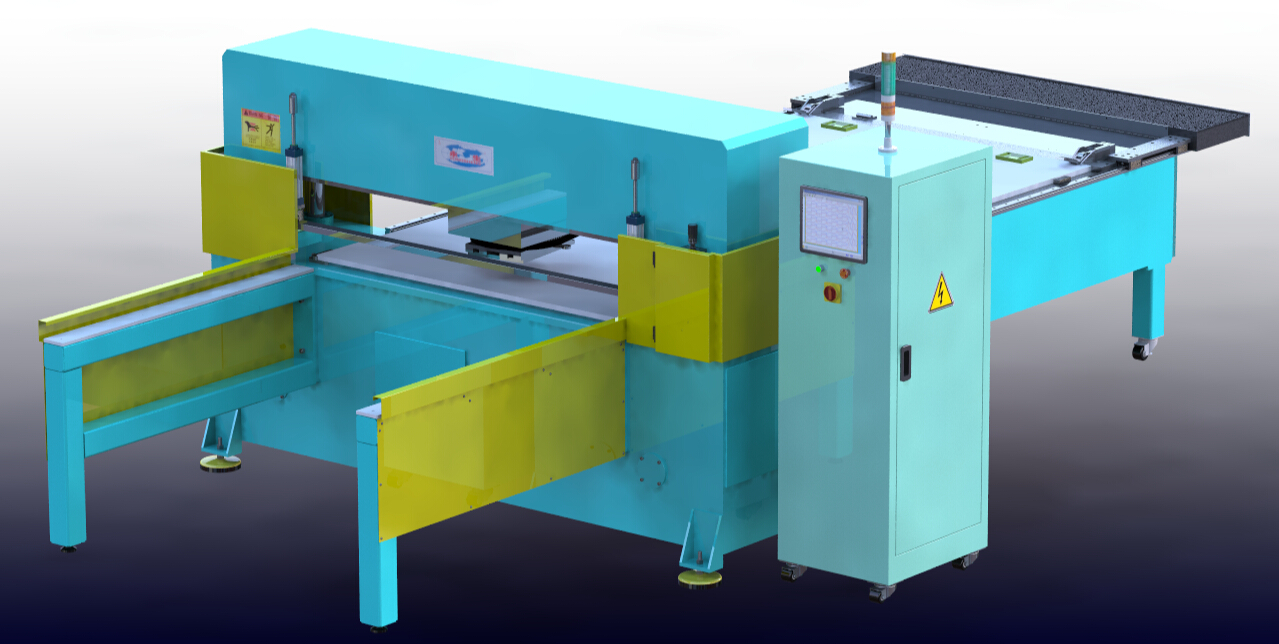

Full automatic cutting machine

The oil pump is damaged.

Generally speaking, the damage of oil pump will be accompanied by abnormal noise. If the downforce of the hydraulic cutting machine is weak, the oil pump will also produce noise, so we should focus on the inspection of the oil pump; The symptoms of some damaged oil pumps are as follows:

No matter how much the pressure is adjusted, there will be no suffocation;

There are a lot of bubbles in the hydraulic oil;

Abnormal noise;

If one of the above three symptoms occurs, the oil pump is likely to be damaged; The damaged oil pump cannot be repaired generally, and can only be replaced.

The reversing valve is damaged or leaking;

The reversing valve is a kind of actuating element. When it is insensitive, leakage will greatly reduce the pressure. At present, there is no good method to detect the quality of the directional valve. It can only be tested by experience or by replacing new parts.

The hydraulic system leaks oil;

Oil leakage of hydraulic system mainly includes:

1. The oil pipe bursts. When the oil pipe bursts, the pressure will be greatly reduced and ZZ will not be able to move. In fact, this is one of the faults of Z maintenance. Open the shield and you can see it at a glance. Replacing the corresponding oil pipe can eliminate the fault.

2. The seal ring is aging and damaged. The aging of the seal ring mostly occurs on the machine that has been used for a long time, and the number of new machines is less. It can be judged according to the service life of the machine.

3. The cylinder leaks oil. The cylinder leaks oil more covertly, which is not easy to find, and the pressure will not find the oil leak. However, experience tells us that the cylinder leaks oil and there are sliding phenomena of varying degrees.