The leakage of hydraulic cutting machine pressure pump mainly refers to the leakage of hydraulic oil. In the work engineering, almost all hydraulic pumps will have similar problems. Its appearance will not stop the operation of mechanical equipment immediately, but will reduce the volume of hydraulic pump, reduce the operating efficiency, and limit the increase of the rated pressure of hydraulic pump.

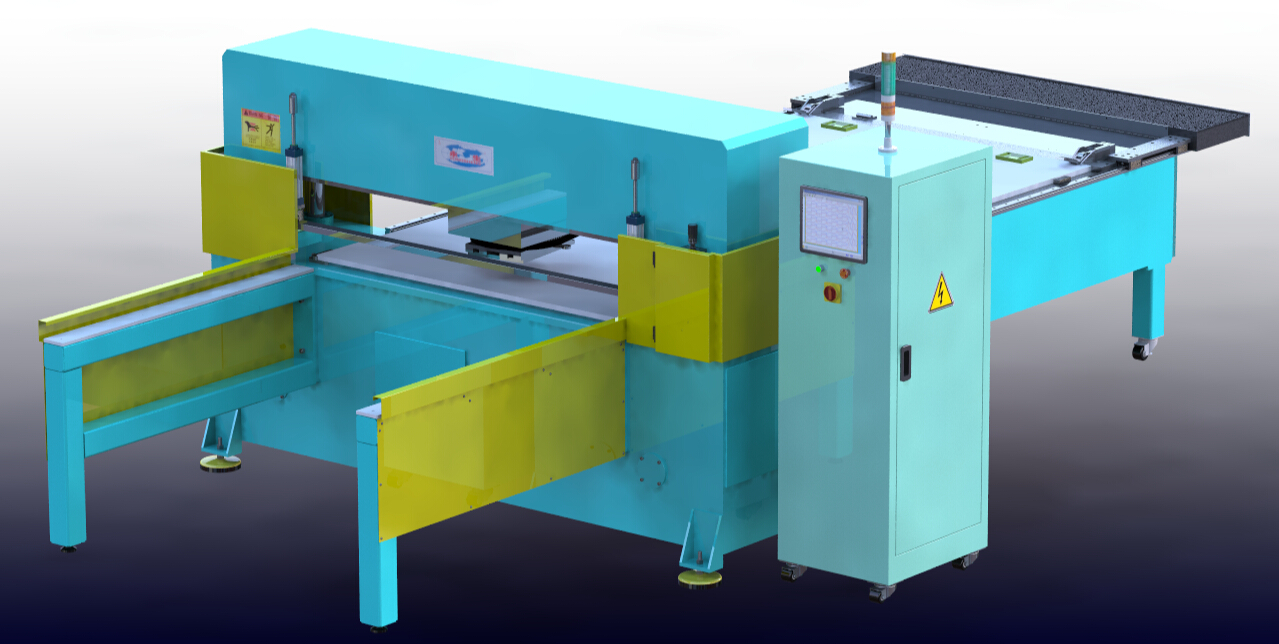

The main reason for the leakage of the cutting machine: since most of the relative moving parts in the hydraulic pump are sealed by clearance sealing, when the hydraulic pump is working, the high pressure oil in the pressure oil chamber must flow through this clearance to the oil suction chamber and other low pressure parts, thus forming the leakage. Injection press cutting machine

Therefore, controlling and reducing leakage is one of the basic conditions to ensure the normal operation of the hydraulic pump. The condition of hydraulic pump leakage is the existence of clearance and pressure difference, and its leakage is proportional to the cubic of clearance value and the first power of pressure difference. The leakage analysis of the pump is mainly from three aspects: the size of the seal clearance, the gap pressure difference and whether the movement increases the leakage.

Because the machining accuracy of the annular clearance between the plunger and the cylinder hole is easy to control, and other clearances are easy to compensate, the volumetric efficiency and rated pressure of the plunger pump are high. The main leakage clearance in the vane pump is the end clearance between the rotor and the port plate, followed by the clearance between the blade and the rotor blade groove, and the clearance between the blade top and the stator inner ring. In order to reduce leakage of medium and high pressure double acting vane pump, some design the port plate as floating port plate to realize automatic compensation of end clearance. Hydraulic cutting machine

The main leakage clearance of the cutting machine plunger pump is the annular clearance between the plunger and the cylinder hole, followed by the end clearance between the axial plunger pump cylinder and the port plate, and the plane clearance between the slipper and the swashplate. For the radial piston pump, in addition to the annular clearance between the plunger and the cylinder hole, there is also the radial clearance between the cylinder block and the port shaft, and the clearance between the slipper and the inner ring of the stator.

Clearance, meshing clearance between two meshing gear teeth. The end clearance of the middle and high pressure gear pump is compensated by an automatic floating compensation mechanism.

For externally engaged gear pumps, the main clearance is the end clearance between the gear end face and the front and rear pump covers or left and right side plates, followed by the radial clearance between the tooth top and the pump body circle.